- MIA UPS™

Universal Palm-Size Heli Frame.

-

-

Version 1 and Version 2

-

- PLEASE

NOTE There are two versions of the MIA UPS frames.

The assembly is the same for most of the frame

construction, except for the main shaft bearing

blocks and LG.

- Version 1 -

had G10 fiberglass bearing blocks, and metal spacers for

the LG.

- Version 2 -

most recent, has the white square plastic Telescopic

tube bearing cups and the LG does not require the metal

spacers since the LG struts are glued on.

- The reason

for making Version 2 was to provide an easier bearing

block for the user and Lighter LG.

- Please study

the photos and test fit all parts first. Make sure you

understand how they go together before Gluing with CA

glue. The assembly photos are self explanatory but

if you have questions, please email us for

clarification.

Version 2

This Kit is

latest and is supplied with pre-assembled bearings blocks to take the Walkera

4G3

ball bearings. There are

some extra white square blocks in the kit, in case you wish to do your

own bearing blocks, for

other size ball bearings, such as for the Walkera 4#3, this would be

useful if you plan to use

this frame for a full brushless 4#3 B conversion or similar.

The options with the MIA UPS™

frame Kit are many. With some imagination it can also work with

other similar small size

helis, such as the Walkera CB100, or the Walkera 4G6- 4#6 with a brushless

motor on the tail.

Note that the 4G6 and 4#6

helis are driven by gears via a torque rod through the boom,

Walkera did this after doing

the motorized tail version with the earlier 4G3, but many people may

find that the geared drive

for the tail, as on the 4G6 and 4#6, is more troublesome to tweak and

repair, and thus one can

convert these back to BL direct drive tails with the MIA Frames for a more

robust and easier to

maintain setup.

I started designing small

electric helis, more than 25 years ago with motors on the tail

because of the simplicity

and ease of maintenance this particular setup offers, especially for

beginner pilots or just

anyone that wishes a more simplistic and easy to maintain setup. The MIA

Robin 280 kit was one such

early kit and several other MIA sizes, which I designed afterwards,

employing a motor on the

tail. Similar configurations followed by other companies for the same

reasons as I described

above. I still prefer motorized tail rotors vs. mechanically driven

tails on

these small Palm-Size helis.

But it is hard to realize the pros and cons of each particular setup,

mechanical vs. motor driven

tails until one tries several RC helis in various sizes and configurations.

Please keep in mind that

today's light-weight technology is offering a lot more in terms of power and

control than it did 10 years

ago. A good BL tail motor coupled with a high resolution, high precision

ESC will provide precise and

instantaneous tail control. In addition, all the MIA Frame Kits are

designed with longer and

more robust booms to add additional natural counter torque control an

minimize work on the tail

section. In many of MIA early G10 frames for the Walkera 4#3, for example,

you could, and still can,

simply go direct drive with a regular stock or BL tail motor, similar applies to

the MIA UPS™

frames.

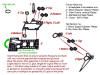

Properly Dressing 4G3 Servos

The Walkera small servos are great, but being that the cases are simply snapped

together with pins, there is the possibility for servo's case to become loose

with use.

To resolve this, follow the tip below, before installing servos on the MIA

upgrade frames , can also be done with the stock frames to clean up the servo

installation and wire routing.

Use a thin band of heat shrink tubing around each servo, in particular the two

rear servos as these have the longer wires. You can use the

MIA Servo Heat Shrink Tubing Kit (in colors) developed for this purpose.

Study the following photos, note how the wires are routed, try not to make sharp

creases in the wires but gentle small radii bends, this allows for a clean

setup.

The New Ball Bearing

Block Details

Some details on the new bearing

blocks, in the development of the MIA UPS™ frames, I

struggled a bit making a final decision on the the final look of the frames,

because the original MIA Upgrade frames had 3/16" square ball bearing blocks

that worked well with the 4#3 smaller main shaft ball bearings, but because the

the 4G3 has larger ball bearings it requires a much larger bearing block.

I didn't want to change the width of the frame support blocks which are also

3/16", because these work perfect with the required location of the 4-3 servos,

both in the Fixed Pitch and CCPM setups. But I needed a way to allow for the use

of larger ball bearings for the 4G3 without disrupting the standard separation

width of the main frames upper vertical plates. I also wanted total versatility

in using the same frame with 4#3 mechanics and other similar size helicopters.

My solution for the ball bearing cups, was to not use the G10 fiberglass ball

bearing pieces as in my original UPS design, Version 1, in previous photos

above, but opted to go with the telescopic white blocks to manufacture the ball

bearing cups for the 4G3 main shaft ball bearings.

Basically the original 3/16" square block , that is used in the MIA Flex and

Rigid original frames, sits inside a 1/4" square block, with ball bearing depth

set by the ball bearing thickness itself, this is separated into two ball

bearing cups, one for the top and another for the bottom. I am very glad I did

this with the white blocks, as described for the ball bearing cups, as this

worked extremely well.

In contrast, the MIA Flex and Rigid

frames come with a 1" long piece of 3/16" square tube with the bearing cups

pre-formed on the block ends, top and bottom.

Two small details I should point out,

the base of the frame as well as the top rectangular G10 plate act as

reinforcements for the ball bearing white block cups, so no need to ever worry

about the white pieces cracking, you can see this in the following photos. This

is probably the only area that I wanted to focus more on since the rest of the

assembly is pretty straight forward, especially if you are already familiar

building my earlier MIA G10 frames.

Because I did not want to increase the width of the frame's main vertical

plates, by going with a 1/4" frame separator main bearing as well as boom

support blocks, I elected to do some cut-outs on the G10 frame, around the ball

bearings, top and bottom, to allow the 1/4" block sections to clear, yet

maintain frame inside wall separation width at 3/16" which makes the

frames very slick, and with direct same G10 material tongue and groove pieces

for the boom supports. This allows the use of larger OD booms, 3/16" OD without

the need for the white square block boom reducers.

In other words, one need not use the white 3/16" blocs as in the original flex

and rigid frames but are supplied in the kits, anyway, as press fit boom

adapters. This means one can use a 3/16 tubular aluminum or carbon boom, or

smaller diameter as in the original 4#3s, or even the original square one in the

4G3. The kits do come with stronger booms as in the Flex and Rigid upgrade kits.

-

-

-

-

-

-

-