I’ve always been in favor of the KIS (Keep It Simple) rule, especially when I started selling kits. This has advantages from many points.

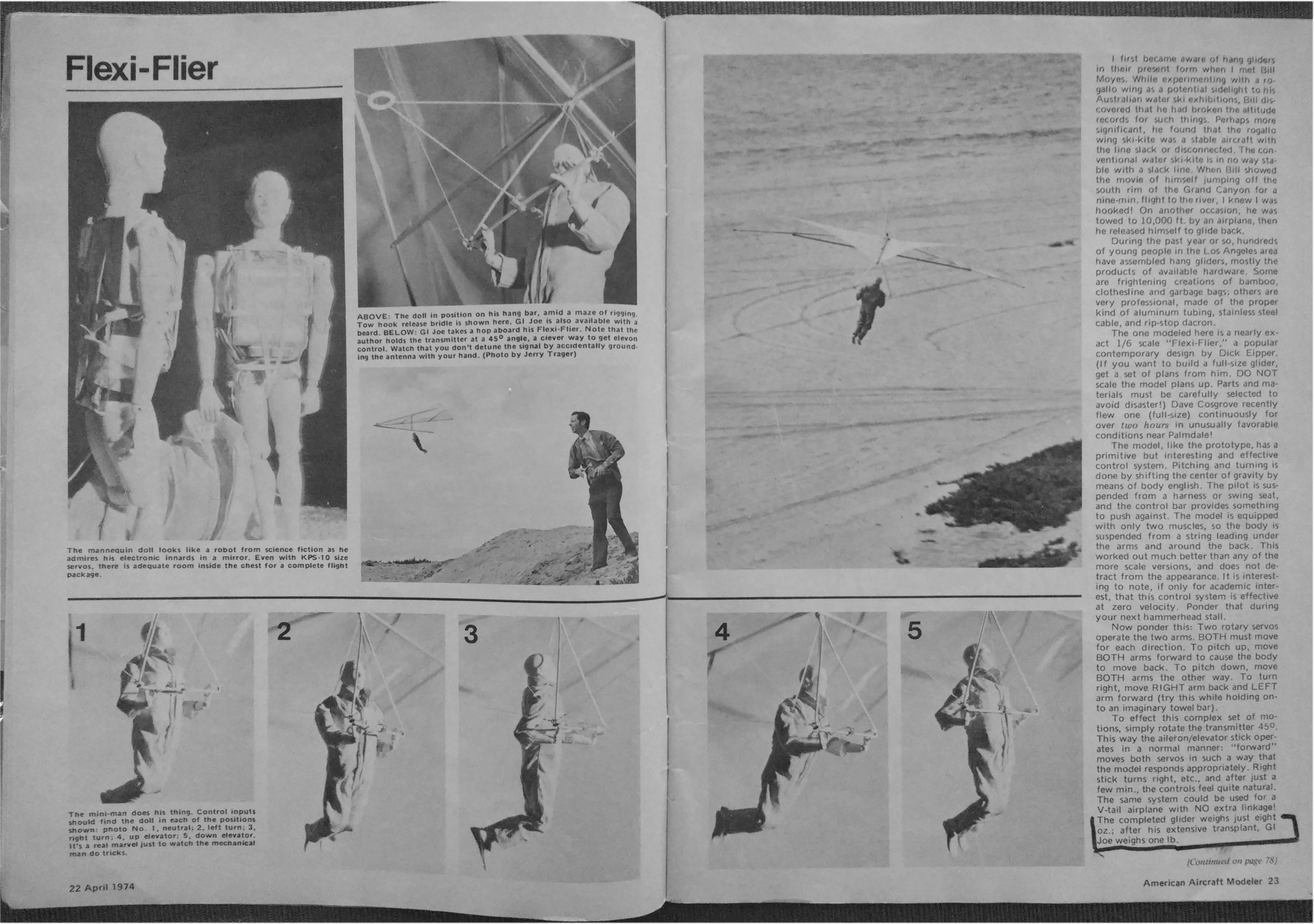

A king-post and cables on the early scale model hang gliders, microlights, ultralights, was something that I wanted to do without, because of the extra complexity in manufacturing, setup and maintenance. Not only extra parts, that protrude on the wing, rob performance efficiency, but can be also distracting and annoying, when traveling with the aircraft or storing it. A full-scale or model wing with a king-post and cabling requires a higher ceiling for storage and transport, wether it be in a real aircraft hangar or inside a car, respectively, unless it is completely disassembled.

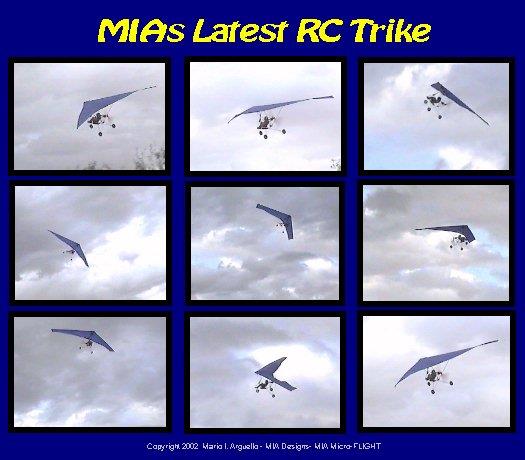

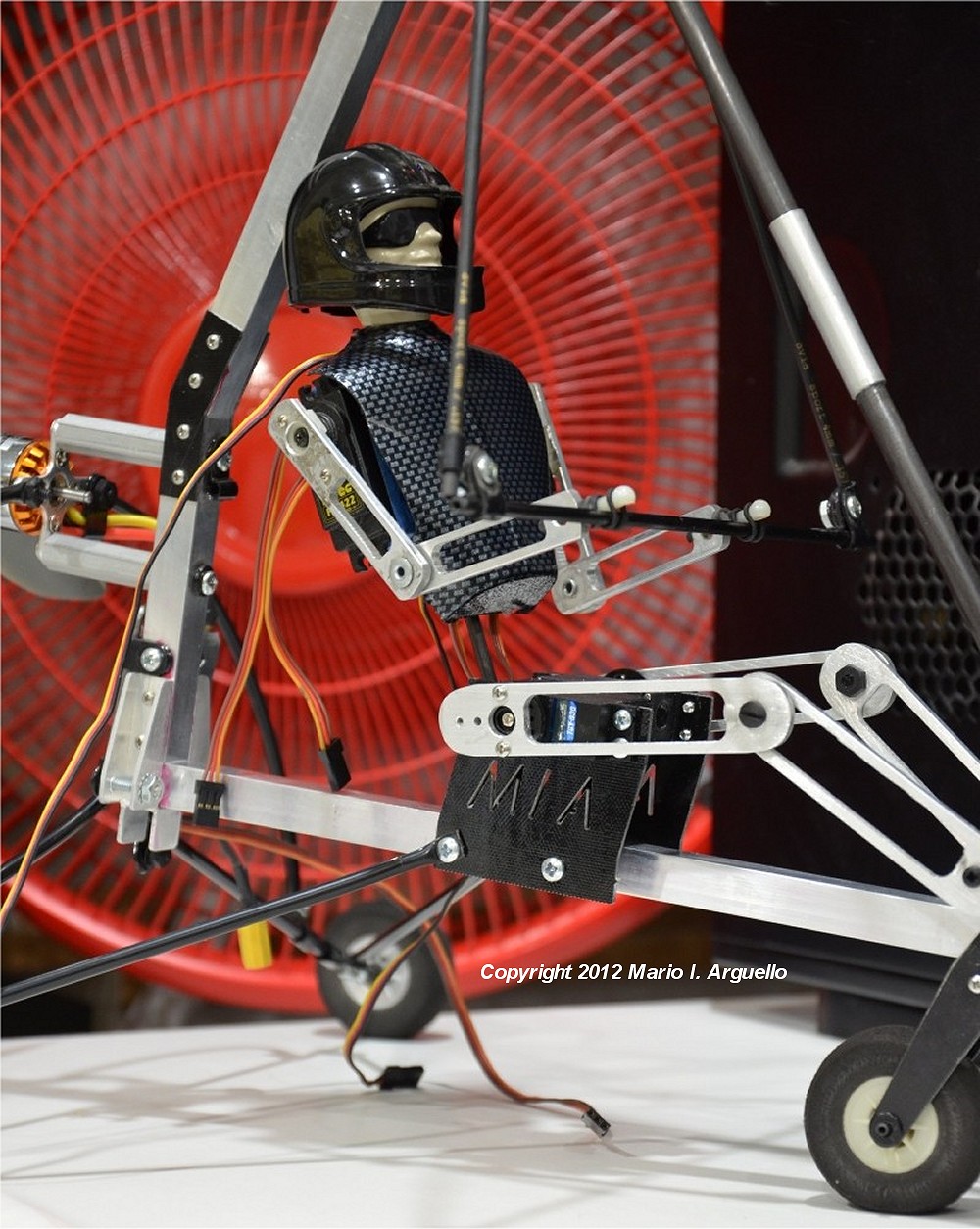

In addition, a floppy wing, as in Rogallo type wannabe RC Microlight wings, do not make an efficient wing, and this bothered me of the early delta type wings, in general. An even though my early first wing of the early 80's was a high aspect ratio wing, it did have a kingpost and upper and lower lines to support the wing, aerodynamically. I wanted not only an efficient, stable, clean wing design, but also one which would be able to recover quickly from a hard dive "safely" and have a reliable degree of control envelope through any type of maneuver. Thus the MIA EZ™ line of RC Microlight wings with SafetySprog™ wing tip washout was born. This feature, amongst other trademark features, such as the MIA Robo™ Pilot, MIA TUFF™ Select Hardware, and some custom pocketing, stiching and proprietary airfoil forming battens, to this day, still hold solid on MIA RC Microlights and other similar MIA products and their effect and performance can be clearly appreciated in the countless videos of such, posted online since 1999. MIA RC Microlights not only fly great but hold tight turns with no degredation in control a a result of all these MIA innovative trademark features.