-

MIA Kit Introduction

Q. Why Build from a kit?

A. Building from kits allows the modeler or user to have full

control of the product assembly. MIA has tried to minimize

assembly complexity by making many of our composite

structured kits "tongue and groove"

with snap in parts that only require "test-fitting" and a

bit of CA glue. In many cases, you only need to snap

parts together and in some of our kits we incorporate

miniature hardware to make assembly even easier. Bear in

mind, though, that we are very careful about the use of

metal hardware on the very small kits such as the micro and

palm size helicopters upgrades (only as needed) because this can also add

unnecessary weight to some products. However, bolt

assemblies on our larger model kits is our preferred way to provide for

a kit that is versatile and easy to assemble and repair.

Building from kits

provides a great deal of satisfaction that you are putting

it together. There is also quite a great deal of information

that can be learned from Kit Assembly. Many times, you can

customize the assembly to your needs and requirements,

or even fix it yourself, in the unfortunate event of a

mishap, such as when you are flying your specific model and

crash.

MIA TUFF™

Upgrades are very durable and almost indestructible,

that we feel very confident, you will not be repairing your

model helicopter, multi-copter, airplane or other product, as often as you do with the stock OEM

parts of the product..

Q. Who are MIA Micro FLIGHT Kits good

for ?

A. For anyone who truly enjoys building and flying RC Models

in general and wants to indulge in the pleasure and learning of

building from a kit.

Because MIA kits use

small parts and may include plastic, metal and composite

materials, the kits are not meant for children, but

preferably for mature Radio Control Model enthusiasts, who

have some knowledge of assembling models which use similar

parts made from similar materials.

Q. What Materials are MIA Micro-FLIGHT Kits made from ?

A. MIA kits are made from Computer Numerically Controlled (CNC)

machined Fiber-Glass or Carbon sheets, for things such main

frames, rotor heads, flex plates, along with stainless steel shafts and molded

high strength co-polymer parts, for gears, rotor hubs, motor mounts, swash plate,

links, and landing gear, for high strength and

durability.

Q. Do I need special skills to build and fly ?

A. No, if you are familiar with building balsa models and already

have some RC model hands on experience, MIA kits will be a breeze.

Q. How long does it take to build from a MIA kit ?

A. Normally

one evening, a few hours, or minutes even, depending on the complexity

of the kit. A landing gear kit for Palm-Size helis, for instance, takes

about 15 minutes, while a MIA Quicksilver Style RC Ultralight kit can

take several hours.

Q. What tools and materials are required to complete a MIA kit ?

A. Standard RC hobby tools such as a hobby knife, scissors,

mini screw drivers, masking tape, ruler, hex keys. mini socket

wrenches, medium viscosity CA glue, and CA

glue accelerator spray to help speed up assembly.

Q. How Durable are MIA Kits and Retrofits ?

A.

MIA Kits are extremely durable, because we use

mostly glass and carbon fiber composites, metal and tough co-polymer

plastic parts, as required, to make both our kits as well as our

retrofit products almost indestructible. All this, combined, allows our

products to withstand use and abuse, beyond what similar standard

mass-produced products offer.

Typical Assembly

Process with MIA Kits

Please read through this

area carefully, but also make sure to follow each Kit's

dedicated instructions.

1)

Inspect the kit

contents with the product descriptions and contents

information next to the specific product, in our site.

2)

Computer Numerically Controlled (CNC) manufactured G10

Fiberglass Parts Trees have small bridges to support the

individual kit pieces. These need to be carefully clipped

with a small wire cutter, or scored with a hobby knife, or

in some cases can be clipped with a small nail clipper or

scissors. DO NOT break the parts with your hands as some

parts come in thin plates, as required for the particular

application, and these need to be carefully removed as just

described to retain part mechanical integrity.

Example from MIA S300 Upgrade Kit for the E-Flite Blade mCX

Helicopter.

Example from MIA S300 Upgrade Kit for the E-Flite Blade mCX

Helicopter.

3) TEST FIT KIT PARTS

FIRST! It is highly recommended that you, first!, test

fit all the parts to ensure proper alignment and, in

particular, orientation for proper product assembly. Because

flat fiberglass plate is cut with a router end mill (similar

to a round drill bit) it is impossible to obtain a perfect

square "inside edge" on a part, where tongue (rectangular)

tabs and groove (round hole) assembly is required.

The best way to have the

parts "sit" or "fit flush" with one another is to slightly

"chamfer" or "countersink" the "groove" holes, with a

slightly larger than the hole diameter drill bit or

"chamfering countersink tool". Many times we at MIA

Micro-FLIGHT do this already for the user depending on the

particular kit.

4)

When satisfied with the fit and proper orientation of

the Kit parts you can go ahead and glue the joints by

spreading a thin bead of CA glue. We highly recommend that

you use the CA glue and Accelerator brand we offer. The CA

bottle has a thin tip and this is ideal for the assembly.

Keep in mind that a clogged CA glue bottle tip or one that

allows glue to flow too much will render a poor quality

joint. Do not use anything else for gluing unless we specify

such in our Kit instructions. In many cases, a disposable

toothpick is ideal to spread the CA glue along an assembly

joint cleanly. Use small clips to hold parts, while drying,

if you do not use an CA accelerator.

When using an CA Accelerator

spread it on one side of the part to be joined with a small

disposable brush or Q-Tip, or even a toothpick. try not to

spray onto the part, as this not only wastes accelerator

material but it spreads unnecessarily into the atmosphere.

Follow CA and Accelerator Manufacturer instructions and use

in a well ventilated area.

Example photos of typical Kit

assembly process.

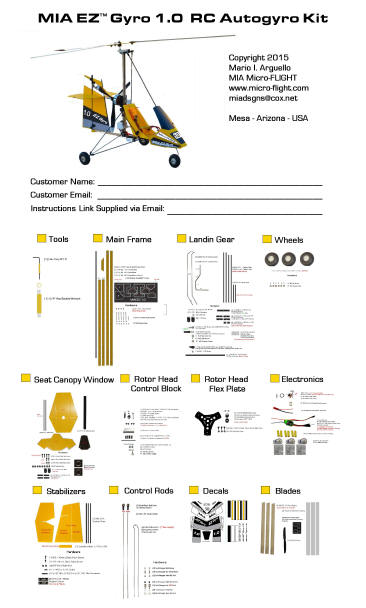

Example of MIA Kit

Contents as Delivered to Customers

Example of MIA Kit

Assembly

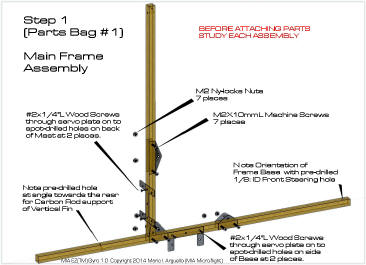

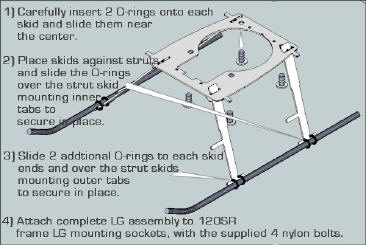

Instructions for Bolt-On (MIA EZ™ Autogyro Kits) and Glue-On (MIA

Micro Heli Upgrades)

If you have any

questions, we'll be happy to answer them via our

E-Mail, or under

Contact MIA